By Jéssica Caroline De Araújo Silva

Text written for the “Scientific Communication Topics” subject of the Post-Graduate program in Science (Microbiology) at thePaulo de Góes Microbiology Institute

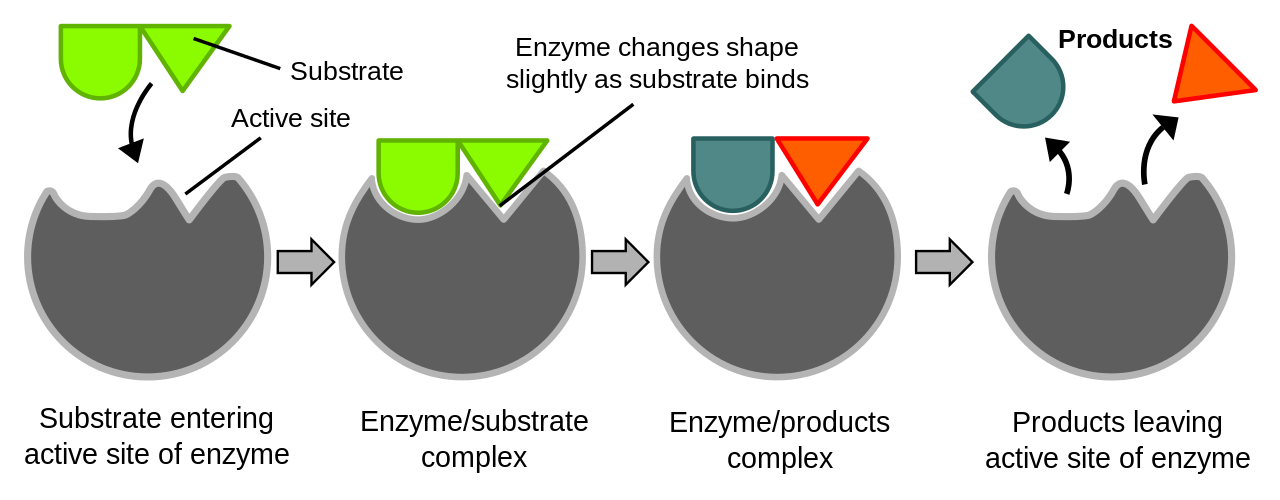

Enzymes are proteins known as biological catalysts due to their ability to promote reactions more quickly and more efficiently. They bind to a substrate in a very specific manner, because they have a region called an active site where the molecules of the enzyme will have high specificity with the molecules of the substrate.This is how the formation of the enzyme-substrate complex occurs and subsequently there is a hydrolysis of the substrate by the enzyme, which results in the release of the product. After the reaction, the enzyme returns to its original state.

Scheme of an enzymatic reaction . Source: http://en.wikibooks.org/wiki/Structural_Biochemistry/Enzyme

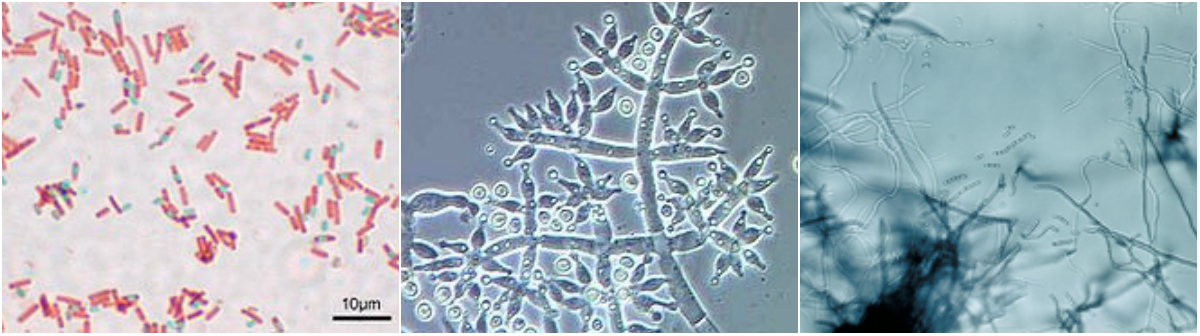

In living beings enzymes play a key role in metabolic reactions, and therefore they are essential to the survival of such beings. In addition, various industries are very interested in enzymes, because they can be used to generate products for a wide range of applications. Industries use microorganisms that produce enzymes in accordance with their business objectives. Bacteria, fungi and actinomycetes have this capability and they are genetically modified, by industries, to produce larger quantities of such enzymes. The bacterial genera such as Bacillus, Clostridium and Pseudomonas; the fungi Aspergillus, Trichoderma and Penicillium; and the actinomycetes Streptomyces and Cellulomonas are used for this purpose and many of these are known for their biotechnological potential.

Bacillus (http://pt.wikipedia.org/wiki/Bacillus); Trichoderma (http://en.wikipedia.org/wiki/Trichoderma); and Streptomyces (http://pt.wikipedia.org/wiki/Streptomyces)

There are several industrial sectors that use enzymes from microorganisms for specific applications: in the textile industry enzymes are able to improve the quality of the fabrics; in the pulp and paper industry they are involved in biomechanical pulping and bleaching; in the food industry they are used in the fermentation processes for the production of bread and drinks such as wine and beer, also they participate in the extraction of substances, such as carotenoids and olive oil; in the detergent industry they have superior cleaning properties, increasing the brightness and removing dirt; they are also used in cosmetics, animal feed, and agricultural industries, among others.

However, today there is much talk about the production of clean energy and biofuels. And one cannot fail to speak about enzymes without making reference to their importance in the production of bioethanol. There are several generations of ethanol: 1st generation – ethanol obtained from the broth feedstock; 2nd generation – ethanol obtained from the by-products of agribusiness; and 3rd generation – microalgae as feedstock for the production of ethanol. In relation to the bioethanol of the 2nd generation, the feedstock can be sugarcane bagasse or straw, wheat bran, dry corn, sawdust and other co-products that are considered to be of low cost but high energy value. During the process of fermentation the cellulase and hemicellulase enzymes, produced by fungi (e.g., Trichoderma reesei genetically modified), interact with the lignocellulosic material of the feedstock chosen, and finally, release the fermentable sugars. In another step, the sugars obtained will be fermented by yeasts (e.g., Saccharomyces cerevisiae) and thus producing ethanol and CO2. This ethanol produced will be used as fuel and is a sustainable source of energy.

Bioethanol. Source: http://www.dreamstime.com/royalty-free-stock-photos-man-biofuel-image18835878

Bioethanol. Source: http://www.dreamstime.com/royalty-free-stock-photos-man-biofuel-image18835878

In the year 2014, the production of bioethanol from 2nd generation began in Brazil on a commercial level. The pioneering cellulosic industrial plants were GranBio and Raízen, and both used sugarcane bagasse and straw as the main feedstock for the production of bioethanol. The prospect, according to the director of the Department of Biofuels from BNDES, Artur Yabe, is that until 2020 the cost of bioethanol production will be lower than that of ethanol. In addition, he says that the income from bioethanol will be greater than that from ethanol, and with the expectation that Brazil will be able to reduce petrol imports as of 2022.

Glossary:

Lignocellulosic material – plant cell wall composed of cellulose, hemicellulose and lignin.

Fermentable sugars – Sugars subjected to fermentation.

References:

JEGANNATHAN, K.R. & NIELSEN, P.H. Environmental assessment of enzyme use in industrial production - a literature review. J. clean. prod. 42, 228-240, 2013.

KIRK, O.; BORCHERT, T.V. & FUGLSANG, C.C. Industrial enzyme applications. Curr. Opin. Biotechnol. 13(4), 345-51, 2002.

KUHAD, R.C.; GUPTA, R. & SINGH, A. Microbial cellulases and their industrial applications. Enzyme Res. Doi:10.4061/2011/280696, 2011.

MADIGAN, M.T.; MARTINKO, J.M.; STAHL, D.A. & CLARK, D.P. Brock Biology of Microorganisms. 13. ed. San Francisco: Benjamin Cummings, 93-94, 2012.

http://www.granbio.com.br/conteudos/biocombustiveis/

http://www.raizen.com.br/energia-do-futuro-tecnologia-em-energia-renovavel/etanol-de-segunda-geracao